Europe’s largest fatigue strength laboratory

4000 sq m of testing area

To configure the optimal testing solution for your part or sample, we mate our over 150 different test rigs to environmental simulations and different types of measurement technology.

Our test labs

Dynamic - the perfect word for SincoTec's testing machine

Burst and Pulsating Spin

max. 45,000 rpm

- Burst Tests

- Pulsating Spin Tests

Components

max. 150 kN

- Resonance test rigs

- High-frequency pulsators

- Torsion resonance and bending resonance test rigs

- Rear-axle and stabilizer test rigs

- Spring test rigs

High Perfomance

max. 2,000 kN / 4,000 bar

- Resonance test rigs

- High-frequency pulsators

- Torsion and bending resonance test rigs

- Internal pressure testing

Hydraulic

up to 500 kN / 200,000 Nm

- Multiple, flexibly configurable t-slot plates

- Singe or multiaxial road load/variable amplitude testing

- Single amplitude tests

Pneumatic

1 N-20 kN / Ways up to 150 mm

- Variety of cylinders and load frame

- Function tests

Railway

- Wheelset axle tests

- Railway components

Our in house production facility and our calibration lab ensure that we can react quickly to your testing needs.

HotShake

- Hotshake tests (catalytic converters and particle filter fatigue tests) following for example VW EP or RAL

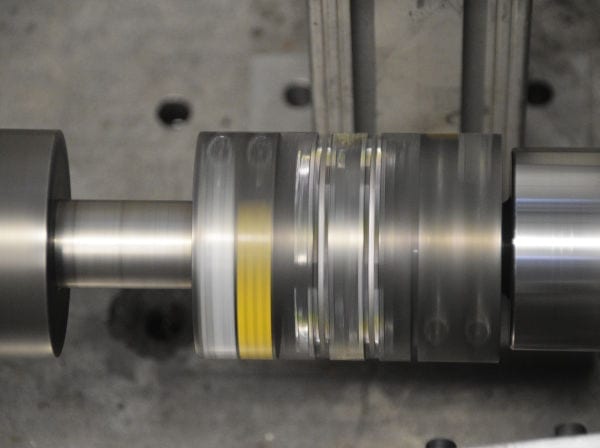

Rotating Bending

- Rotary bending tests

- Bearing tests

- Frictional torque tests

Vibration

- Shaker

- Shock and NVH-Tests

- Transport simulations

Internal Pressure

- Internal pressure testing

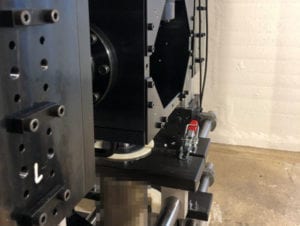

Crankshafts

- Torsional change test rig

- Bending changes test rig

- Torsional bending test rig

Other Services

- Battery and other hazardous material tests

- Multiaxial tests

- Custom solutions

Contact Us

We have testing solutions for all manner of components, assemblies, and materials to determine their maximum load capacity, lifetime, and reliability. Contact us below with a summary of your testing needs and we will reach out to you as soon as possible.

Expert engineers, continuous innovation, synergies within the SincoTec Group

Our team of 45 expert engineers and fatigue strength specialists combines the 150+ different test rigs we have with our toolbox of modular components and custom parts to develop the testing solution for your needs.

SincoTec offers unique synergies integrating our calibration lab, working to DAkkS standards, our production facility, and our cooperation with the affiliated SincoTec Test Systems GmbH. Test Systems can quickly develop test rigs to specific client requirements for use in our fatigue strength lab.

A flat corporate structure ensures that information and solutions are developed quickly and our many patented test and measurement procedures showcase our innovative capacity.

Join us in our lab so that you can get a better understanding of our testing options.