Test standards

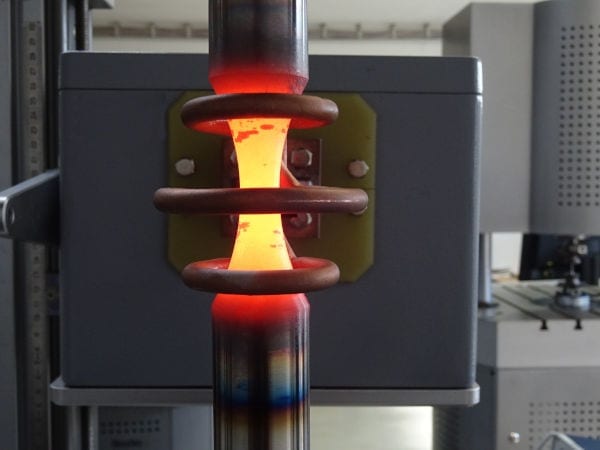

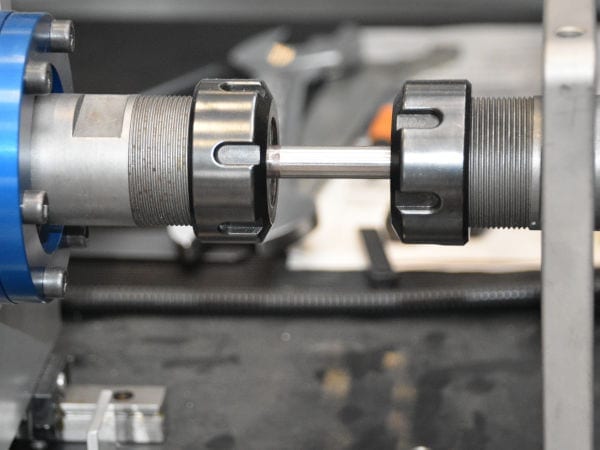

To safeguard your manufacturing process, quality and test standards should be developed that are experimentally proven and statistically verified. Our test protocols determine how test rigs and fixtures are used, the actual testing procedures, how test data is evaluated, and what statistical values we are seeking.

Test protocols developed according to both the cutting edge of scientific research and economic parameters are essential for the development of new components and assemblies. SincoTec develops test protocols and devices that exactly meet your demand and are based on the latest research on fatigue strength.

Our services

- Analysis of data from operating load experiments to determine the critical forces and moments

- Development and production of test rigs and fixtures

- Calculation of test loads

- Creation of efficient test methods to obtain statistically useful test results

- Establishment of guidelines and specifications for the statistical evaluation and summary of test results

How can we help you?

When it comes to testing your products, components or component groups on their load capacity, lifetime and reliability that‘s where we have the right solution. Please shortly tell us about your problem and we will reach out to you as soon as possible!