Typical Applications

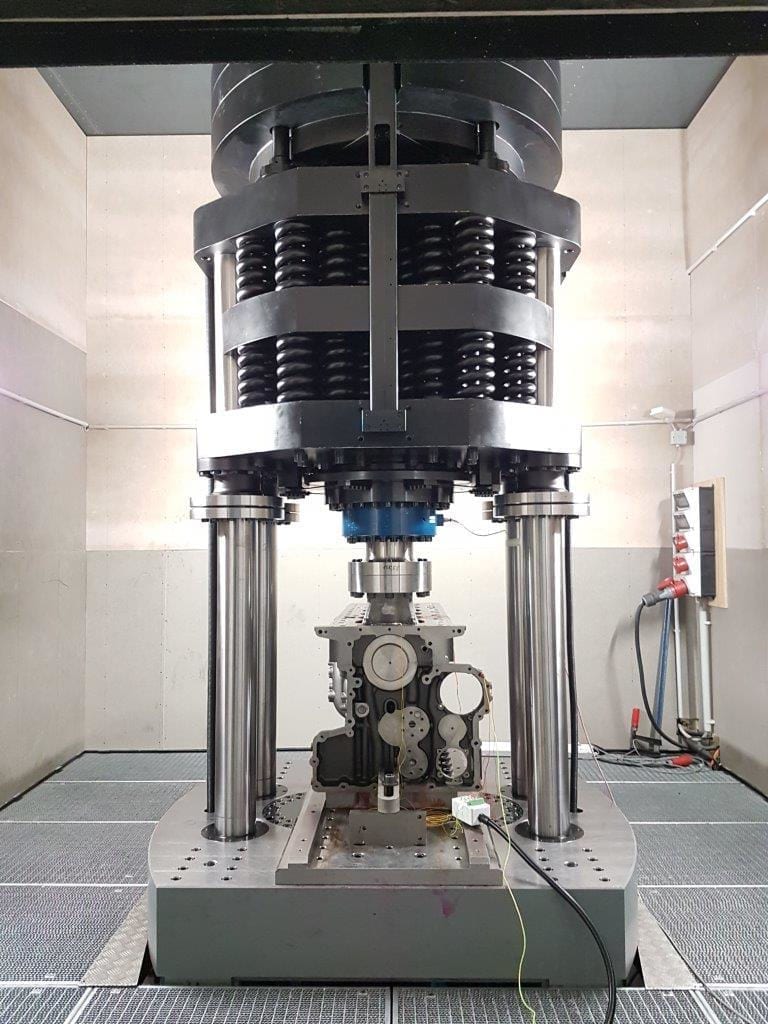

Crankcases

Crankcases are very complex components. Crankcases must not only sustain the thermal changes occurring between combustion and cooling but also the abrupt bearing forces of the crankshaft.

SincoTec developed the POWERSWING MOT, up to 2,000 kN, to test crankcases in a manner mimicking these conditions.

Quick results with crack detection, at high cost-efficiency.

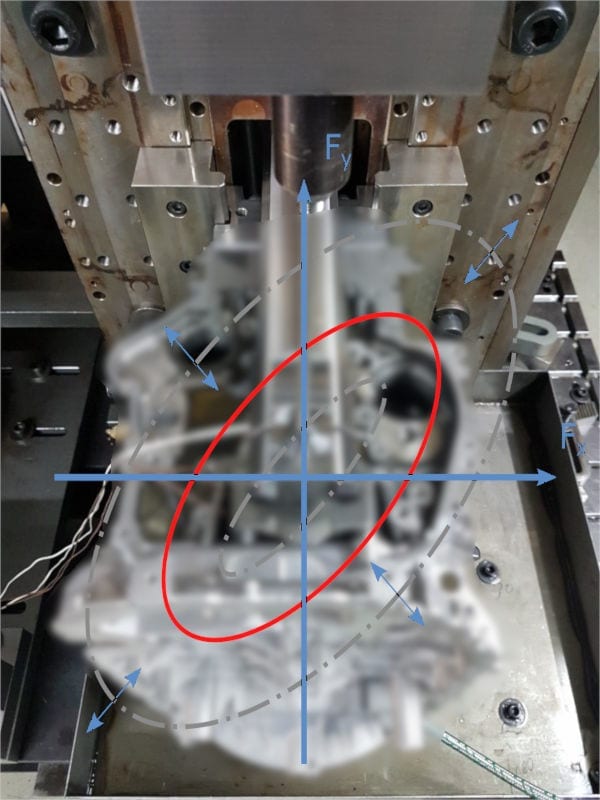

Biaxial tests

Tests can be carried out biaxially to closely replicate crankcases’ operational environment.

The resulting elliptic power curve replicates the impact of the firing order on the crankshaft which simulates in detail the real-life failure case of crankcases.

Advantages of testing using the resonance principle:

- Quick

- Cost-efficient

- With crack detection

Do your components need to be tested?

- We have testing solutions for all manner of components, assemblies, and materials to determine their fatigue strength, maximum load capacity, lifetime, and reliability. Contact us below with a summary of your testing needs and we will reach out to you as soon as possible.