Component-specific test systems

Testing machines for industrial bearings

Test systems for industrial bearings need to be as versatile and offer as diverse an array of loads and stresses as those bearings experience in the operational environment. To meet these requirements, SincoTec offers a variety of custom-developed test rigs for industrial bearings.

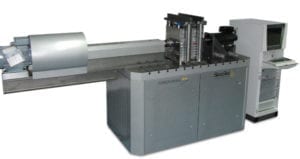

POWER ROTORQUE

Radial

Torsion

for multiaxial testing on industrial bearings

- Rotation test system with combined, high-frequency radial and torsional oscillation

- For multiaxial testing

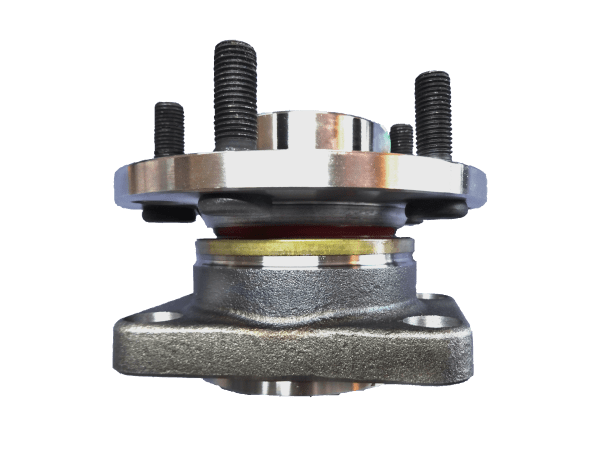

Typical Components:

- Rolling elements

- Bearing housings

- Tracks

POWER ROTORQUE

high performance

Radial

Torsion

for multiaxial testing on bearings used in wind power generation

- Rotation test system with superimposed, high-frequency radial and torsional oscillation

- For multiaxial testing

Typical Components:

- Rolling elements

- Bearing housings

- Tracks

POWER BEARING measurement

Rotation

for measurement and endurance testing on damper bearings in suspension struts

- Highly precise frictional measurements during testing

- Oil conditioning (temperature, pressure)

- Servo hydraulic test system

POWER BEARING hydrodynamic

Rotation

Axial

for triaxial testing on hydrodynamic plain bearings

- Applications requiring high revolutions per minute

- Block programs

- Axial and radial forces

- Oil conditioning

- Servo hydraulic test system

POWER BEARING high speed

for high-speed testing on industrial rolling bearings under radial or axial loads

- Highly dynamic test system

- Precise lubrication system and oil conditoning

- Servo electric test system

POWER BEARING multi axial

for 5-axial testing on plain bearings of the main rotor shaft of wind turbines

- 5x 1.5 MN test force

- Oil conditioning

- Machine weight 85 t