Typical Applications

Bicycle frames

Both the driver and their driving style exert high loads on bicycle frames. The rapid adoption of e-bikes, and the corresponding increases in average speed, have further heightened the resulting loads on the frame and other components. Inexperienced drivers may also expect their bicycles are able to sustain heavier loads than they are designed to, further stressing the frame. This stress field increases the necessity of testing individual bicycle components.

Our 10 years of experience conducting bicycle components tests are complemented by the activity and expertise of our advisory board which contains a well-known German consumer protection foundation.

Our capabilities

Testing according to Norms ISO 4210, EN 15194, DIN 79010

Commonly tested components:

- Bicycle forks

- Handlebars and stem units

- Seat posts

- Drive units

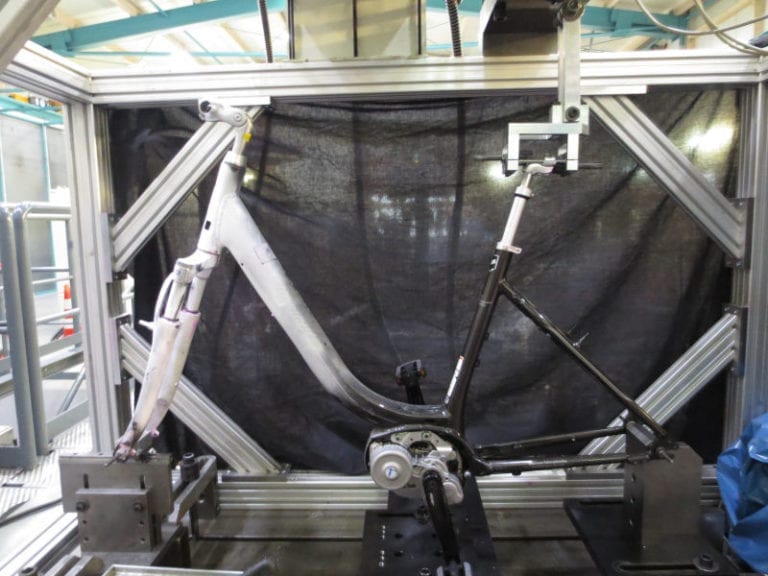

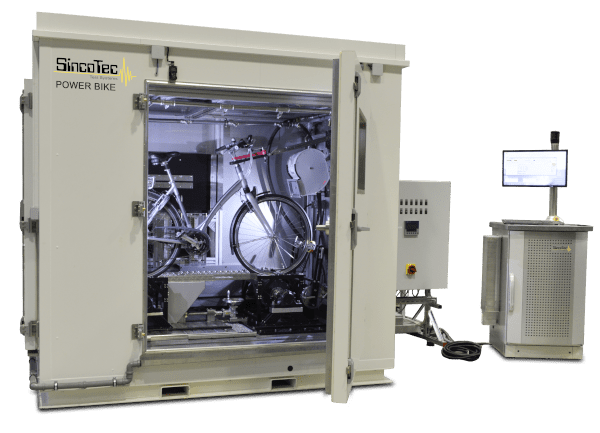

Bike test rig with environmental simulations

POWER BIKE

- Mechanical tests in which bicycles can also be overloaded

- Rain simulations

- Temperature simulations

- Load increasing/decreasing cycles testable

- Recuperation tests

Do your components need to be tested?

We have testing solutions for all manner of components, assemblies, and materials to determine their fatigue strength, maximum load capacity, lifetime, and reliability. Contact us below with a summary of your testing needs and we will reach out to you as soon as possible.