Typical Applications

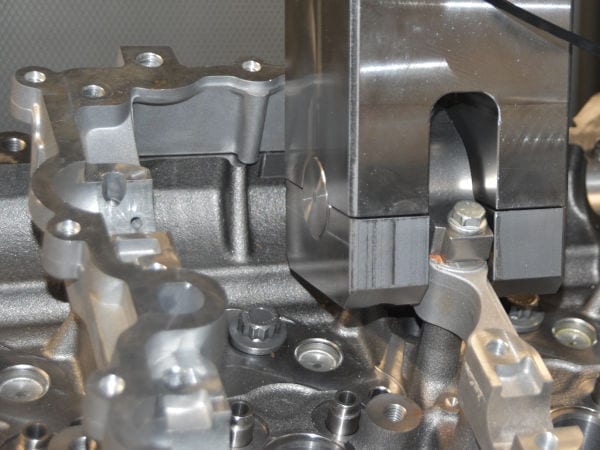

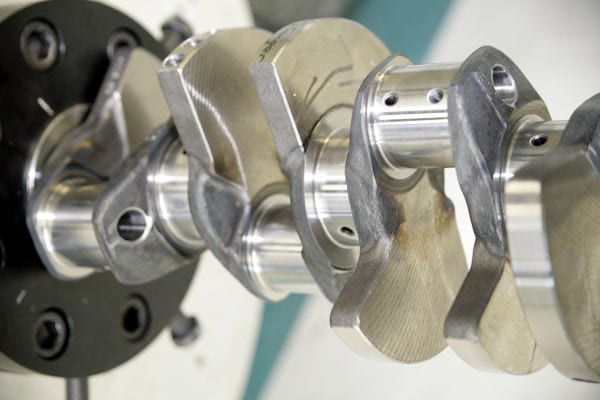

Crankshafts

SincoTec’s crankshaft bending and crankshaft torsional resonance test rigs have become the global standard in crankshaft testing for research and development and quality control purposes.

Our capabilities

Test rigs

The dynamic strength of passenger cars and commercial vehicles crankshafts can be tested with frequencies up to 100 Hz.

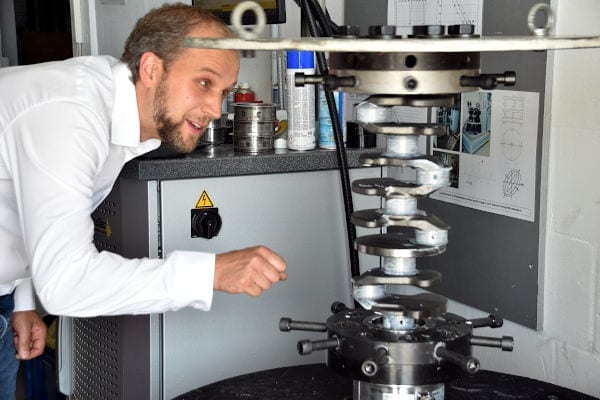

For different R-conditions, we use our electromotive universal pulsator POWER SWING MOT.

Torsion and bending

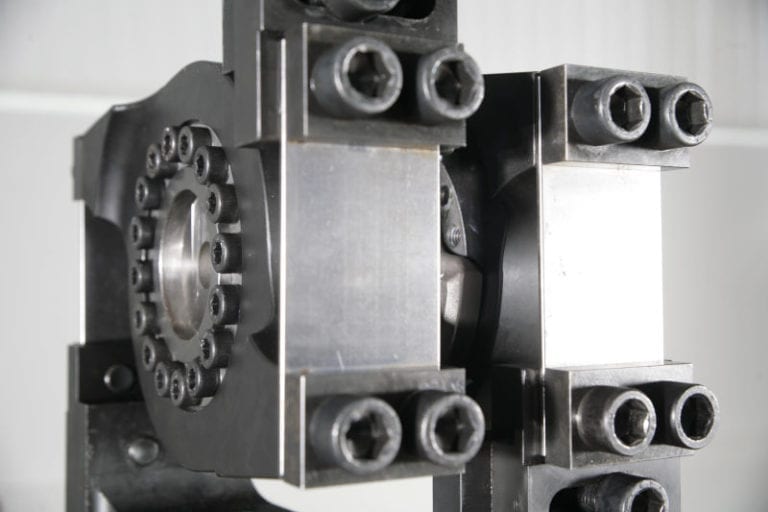

The biaxial test system TORBEN allows you to initiate phase-synchronized bending and torsional loads with frequencies up to 50 Hz. This test allows you to determine the fatigue endurance limit of a component, which is otherwise very difficult to calculate.

Custom solutions

Our team of expert engineers and technicians is always innovating and ready to design custom test systems that meet your testing specifications.

Commonly tested components:

- Crankshafts

- Camshafts

- Joint connections

- Welded connections

Do your components need to be tested?

We have testing solutions for all manner of components, assemblies, and materials to determine their fatigue strength, maximum load capacity, lifetime, and reliability. Contact us below with a summary of your testing needs and we will reach out to you as soon as possible.