Environmental simulation testing

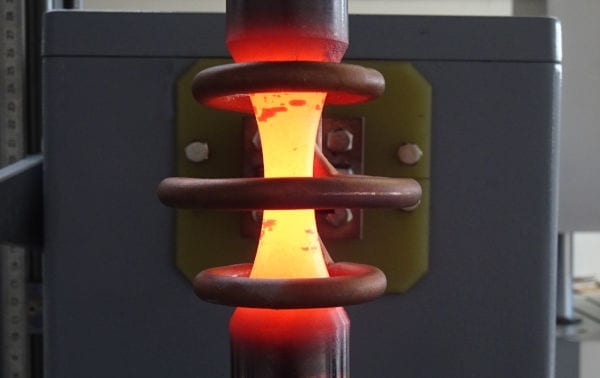

Recreating a components failure case may require adding environmental simulations to your testing if mechanical loads are not the only ones experienced by your components. Both weather (e.g. temperature, humidity) and other environmental factors can be recreated in our lab to accurately simulate your component’s operating environment.

Our capabilities

Temperature

Your component’s operational environment, in a lab

- Temperatures between -70 – 1400 °C

- Temperature and climatic chambers

- Hot air blowers

- Oil/gas burners

Testing with mediums (according to norms)

Combine mechanical and chemical interactions

- Salty water

- Dirty water

- Nitrogen

- Hydrogen

- etc.

Combinination with mechanical test rigs

Environmental simulations can be integrated into almost every form of testing we conduct.

Components can be subjected to both dynamic loads and environmental factors in parallel ensuring that testing closely replicates the component’s operational environment.

Contact us

We have testing solutions for all manner of components, assemblies, and materials to determine their maximum load capacity, lifetime, and reliability. Contact us below with a summary of your testing needs and we will reach out to you as soon as possible.