Determining service loads

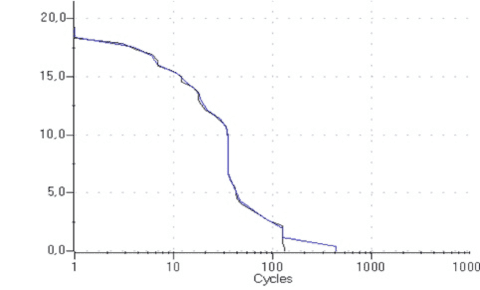

Dynamic fatigue tests are used to prove that new components can sustain the loads they will experience in their intended use over the entirety of their lifecycle.

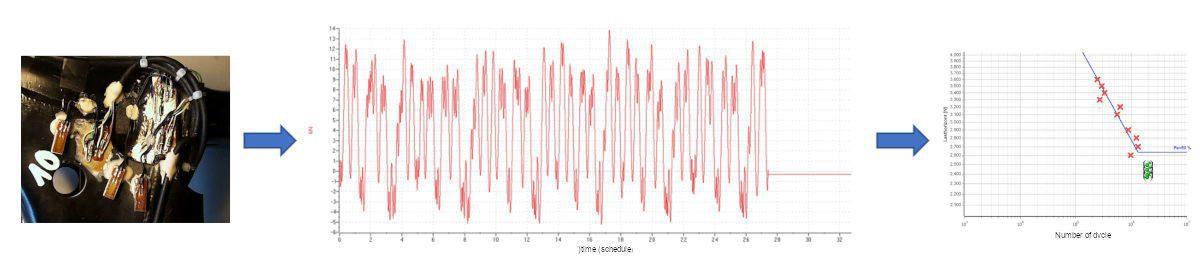

For simple components, a single simulation often suffices to determine the operational loads the part will endure. Complex components generally require the use of, e.g., strain gauges, displacement sensors, and accelerometers, to determine operational loads. Analyzing this data allows us to determine the experimental load for testing.

Procedure

- Analysis of a component with respect to the critical stress it experiences

- Installing measurement instrumentation at critical points of the component to measure stresses

- Recording components operational data

- Analysis of gathered data to determine load spectra

- Derivation of experimental load to begin preliminary testing

How can we help you?

When it comes to testing your products, components or component groups on their load capacity, lifetime and reliability that‘s where we have the right solution. Please shortly tell us about your problem and we will reach out to you as soon as possible!