Typical Applications

Connectors

Connecting elements are responsible for safely transferring forces and moments across components or assemblies without damage.

Screws

The ability of screws to withstand conditions such as corrosive conditions such as salt spray or humidity, freezing temperatures, or very high temperatures, must be verified. These types of demands are placed on screws used in the automotive, aerospace & space flight, green energy, and medical technology industries.

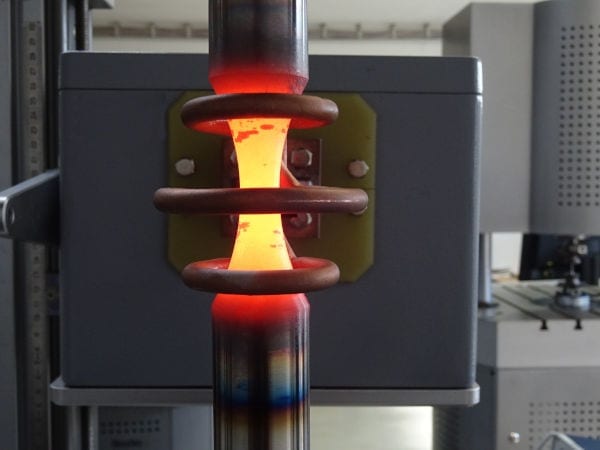

In our accredited test laboratories, we test all sizes and types of screws under different loads and environmental conditions. These tests are carried out on high-frequency resonance pulsators which can reliably detect the smallest changes or cracks, carrying out the test quickly and safely.