Fatigue Test

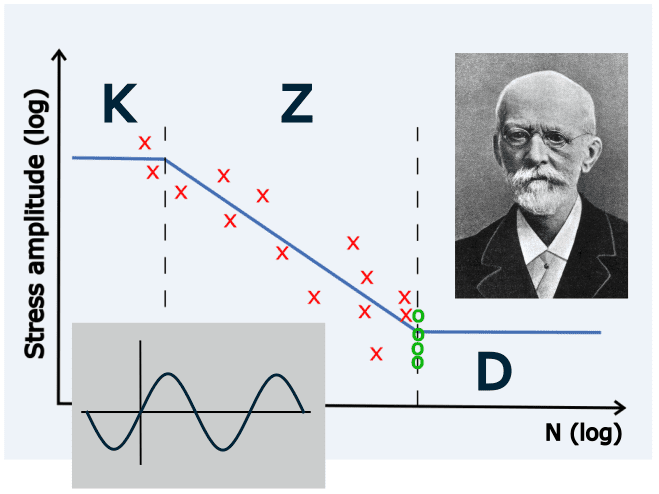

For the operationally stable design of a component, a fatigue test is performed where test samples are loaded cyclically. This is usually done under a sinusoidal stress-time function to find the components dynamic properties. This procedure is also called the Wöhler test, after its inventor August Wöhler.

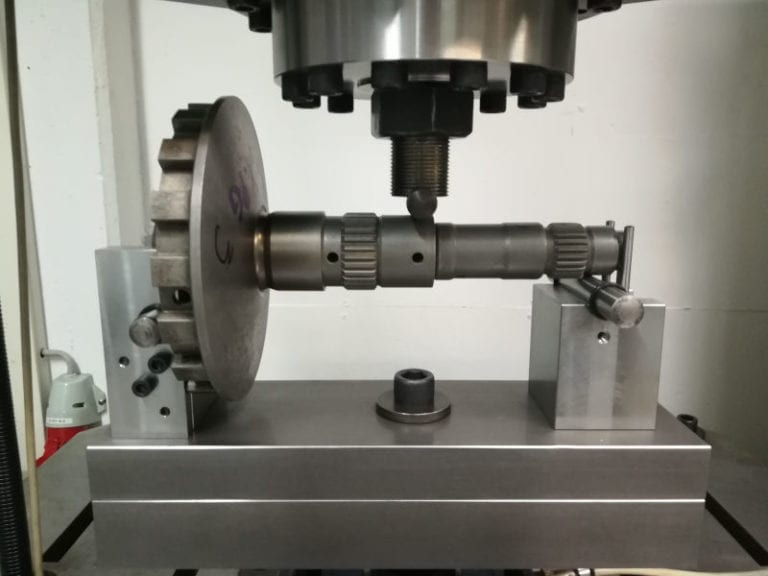

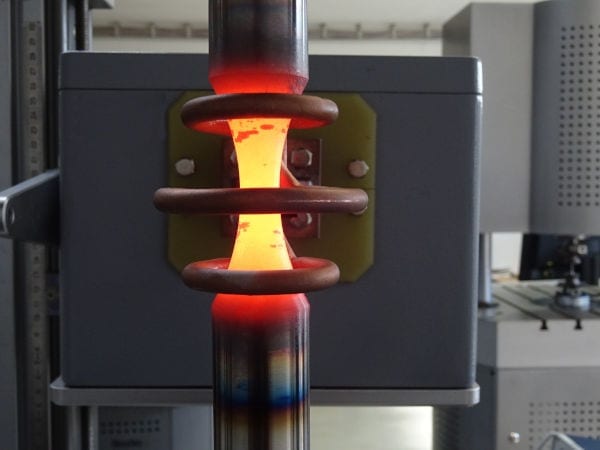

Performing the Fatigue Test

Fatigue strength tests with constant amplitude are carried out to determine the fatigue strength and fatigue resistance of materials, components or systems. This Wöhler test is continued until a defined failure of the sample occurs. This can be a fracture or a crack of a defined length. If a predefined number of cycles is achieved without a crack or fracture, the sample is referred to as a run-out sample.

The S/N-curve

Sum of tolerable load cycles until Crack

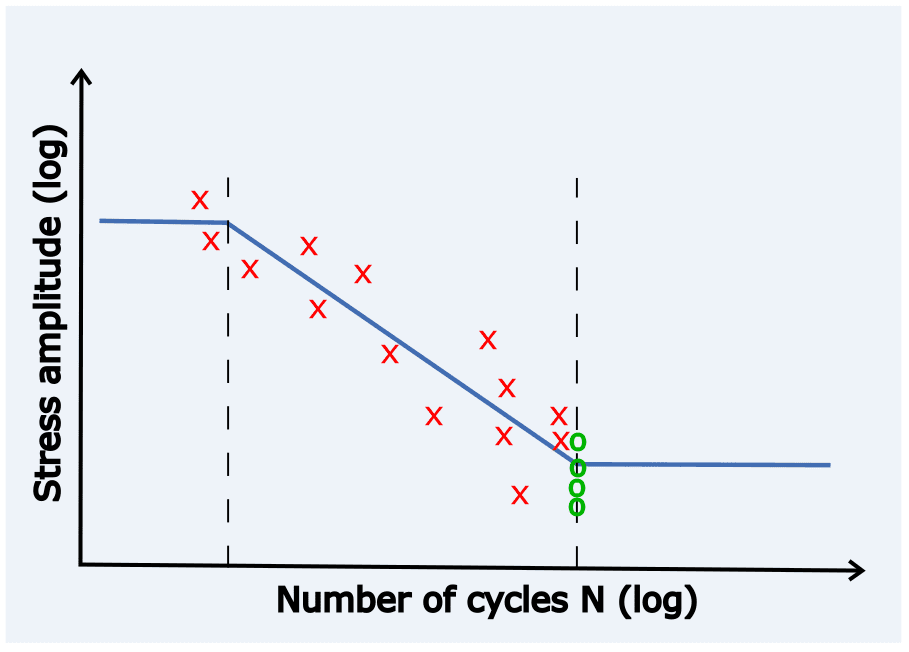

During the fatigue test, several samples are loaded in the same way at different load levels until failure of the sample occurs.

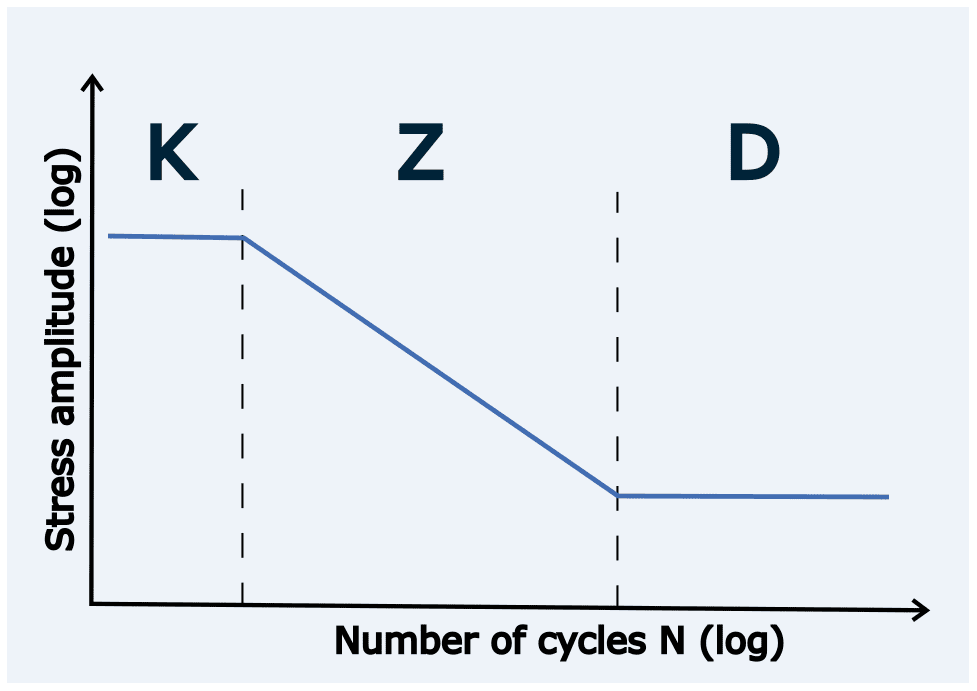

The combination of the load level and the endured cycles are represented as a S/N-curve. This is plotted double-logarithmically in a coordinate system of S (load) and N (cycles) and is composed of the ranges of low cycle fatigue (K) , finite-life fatigue (Z) and high cycle fatigue (D).

The S/N-curve depicts the dynamic properties of a component and provides information on how many cycles a component can endure at a given load level.

Low Cycle Fatigue (K)

< 100.000 load cycles

Components that are subjected to very high stresses are usually only designed in the short-term strength range. They can withstand extreme thermal and mechanical loads, but only for a comparatively low number of load cycles.

The short-term strength is determined by means of low-cycle fatigue tests.

Finite Life Fatigue (Z)

100.000 – 2.000.000 load cycles

The cyclic stress value that can be tolerated for a given number of failure cycles, taking into account the crack or survival probability.

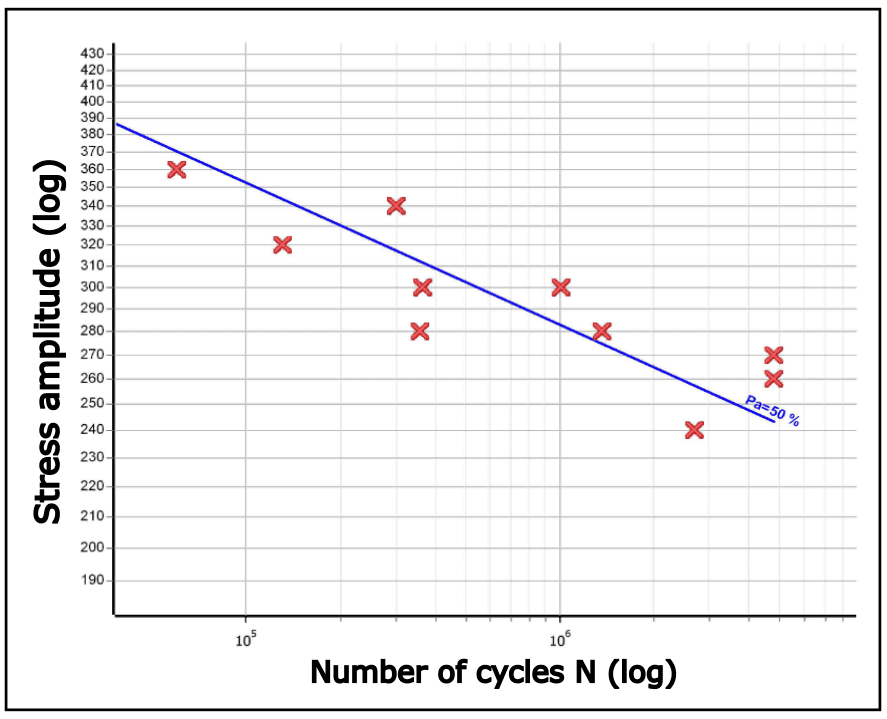

The fatigue strength is determined by continuous fatigue tests (high-cycle fatigue test). To evaluate the results, the pearl string method can be used, for example.

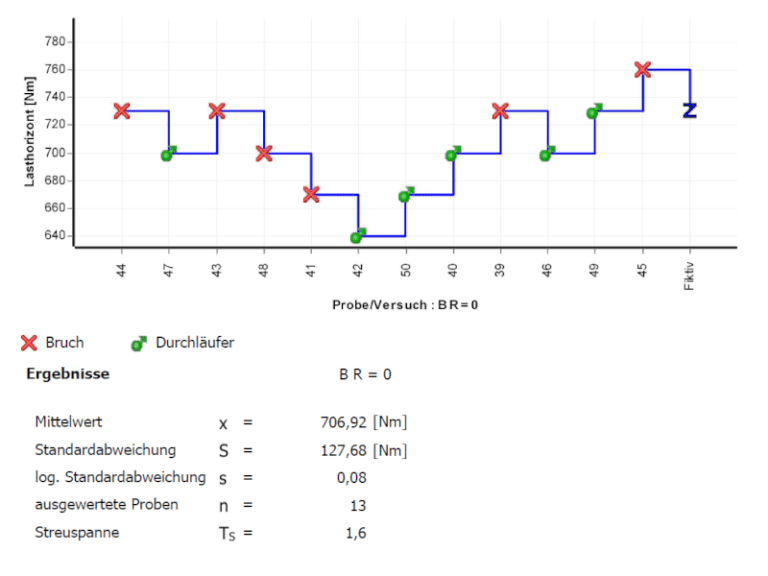

Pearl String Method

After a fatigue test has been performed several times at different load levels, the values obtained can be plotted in a double logarithmic diagram. With the help of a regression, the fatigue line is then optimally placed in the scatter.

High Cycle Fatigue (D)

> 2.000.000 load cycles

The high cycle fatigue strength describes the largest stress amplitude that can be endured an infinite number of times or up to a specified limit number of cycles at a specified mean stress or specified stress ratio.

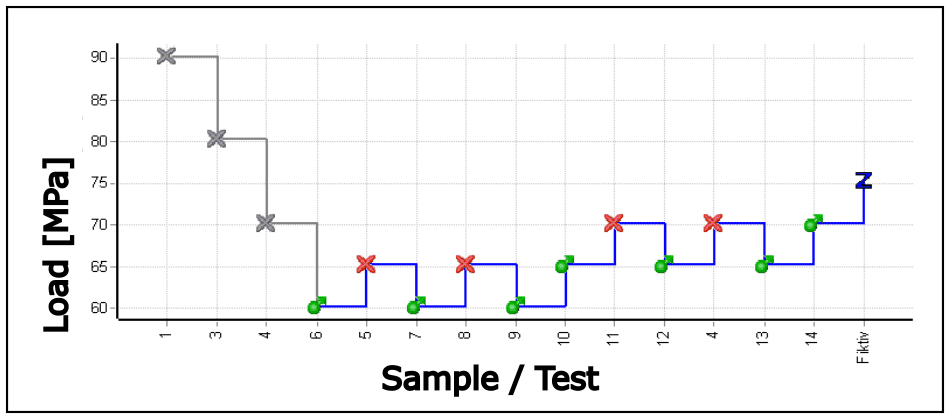

The fatigue strength is determined by means of high-cycle fatigue tests. For example, the staircase method can be used for this purpose.

Staircase Method

The staircase method is based on follow-on tests. Depending on the result (crack or run-out), the load must be reduced or increased. The step increase should not be greater than 8% of the load. With the help of this method, the limit to fatigue strength can be approximated.

How can we help you?

When it comes to testing your products, components or assemblies for their load capacity, service life and reliability, we have the right solution. Please briefly describe your problem, we will be happy to get back to you in a timely manner!