Rails & welded joints tested for infinite fatigue life – for greater safety in rail transport

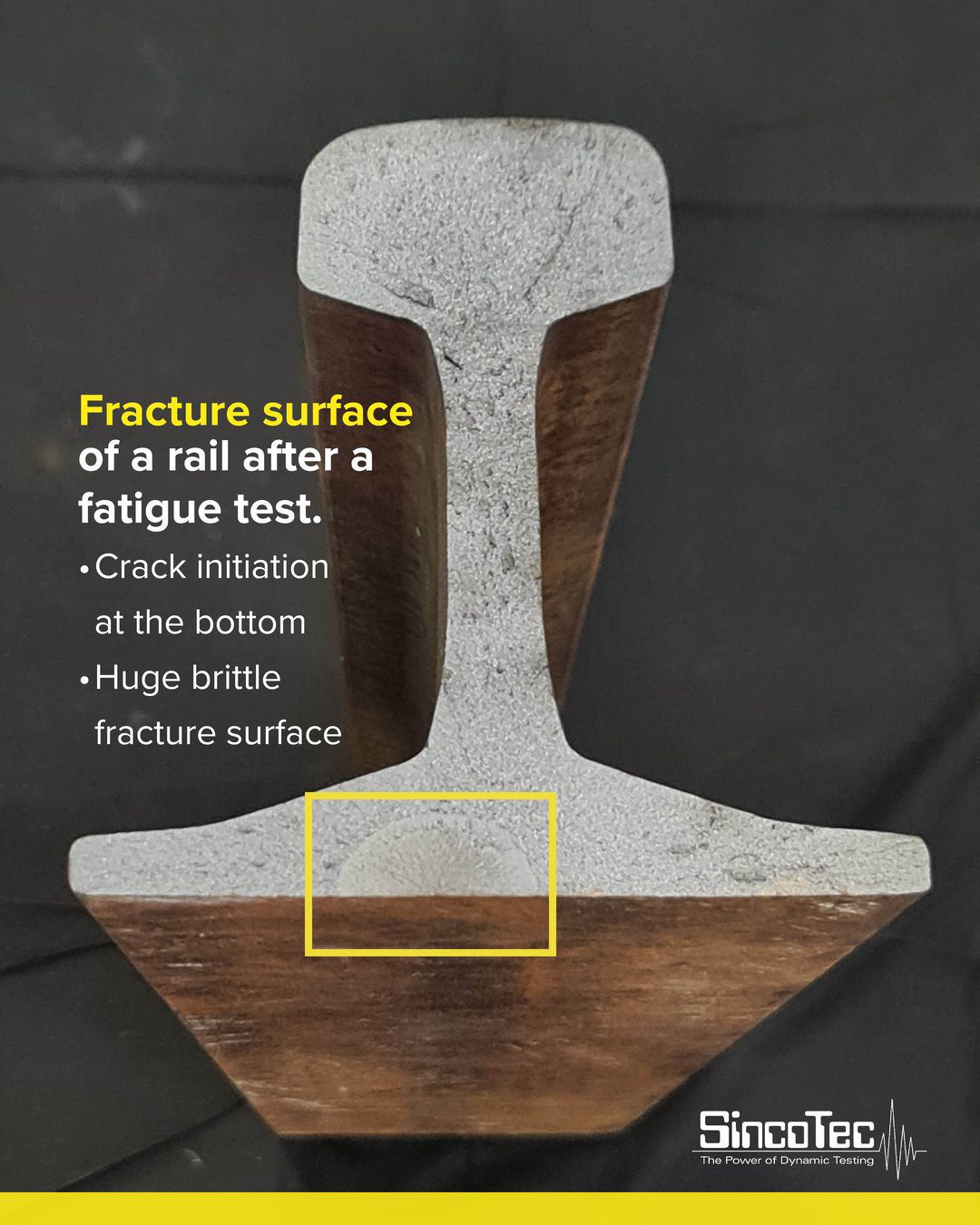

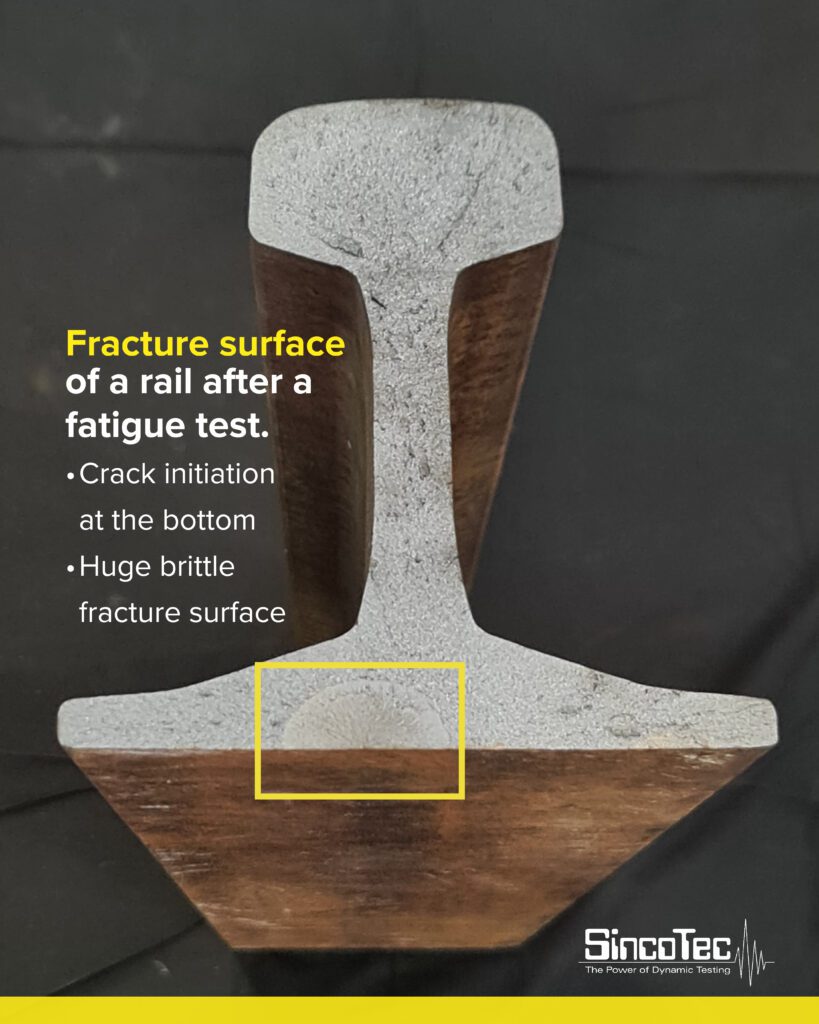

We are currently performing fatigue tests on rails in our fatigue testing laboratory. In doing so, we investigate whether the rail can withstand the many cyclic loads under environmental influences up to the fatigue limit. Rails must be designed for infinite fatigue life.

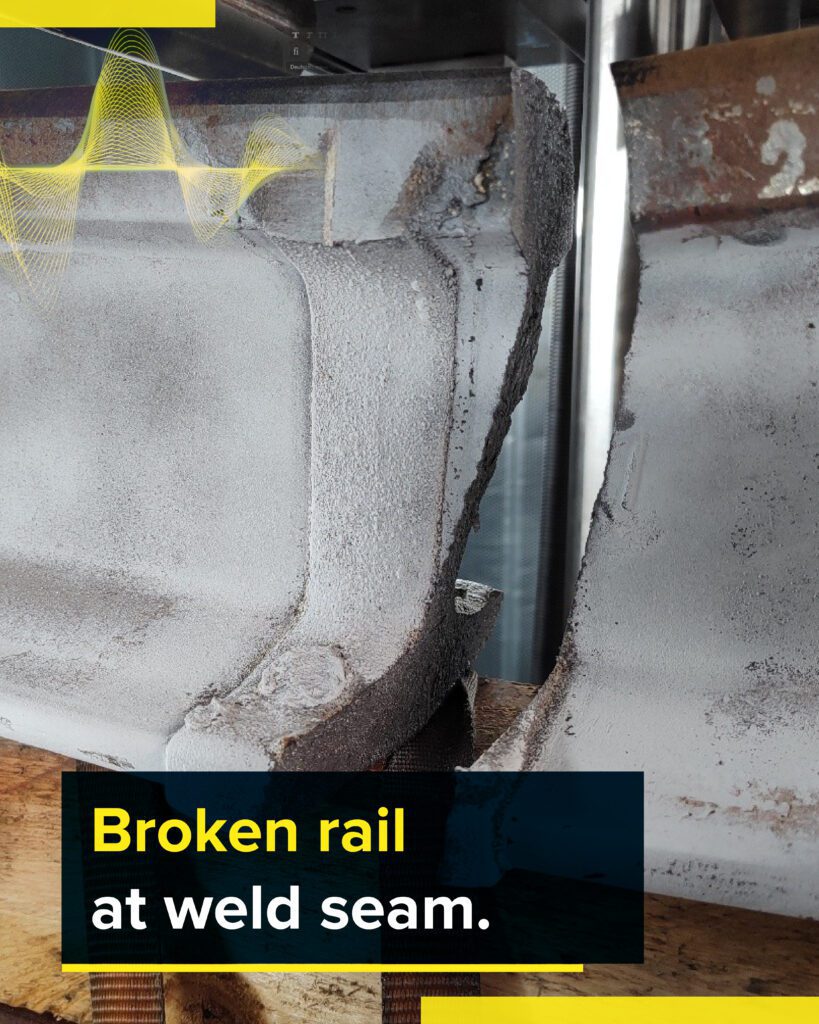

When a train runs over a rail, the rail deflects under the axle load and is therefore subjected to bending stress. The higher the train weight, the greater the load. In our tests, we can apply 40 bending load cycles per second, which corresponds to the bending loading during the passage of a high-speed train (approx. 8 cars). To verify the fatigue limit, we apply 5 million load cycles in a short time — quickly and efficiently. This means the 2-day test corresponds to the passage of 125,000 trains. The most critical areas of a rail are the welded joints, as the strength is lower there.

After our first rail testing applications using the POWER SWING resonance testing machine, we have now carried out extensive test series for various customers:

👉 Over 30 rail specimens — welded and non-welded segments — were investigated for fatigue behaviour and fatigue life up to fracture. Both newly rolled rails and in-service rails were tested.

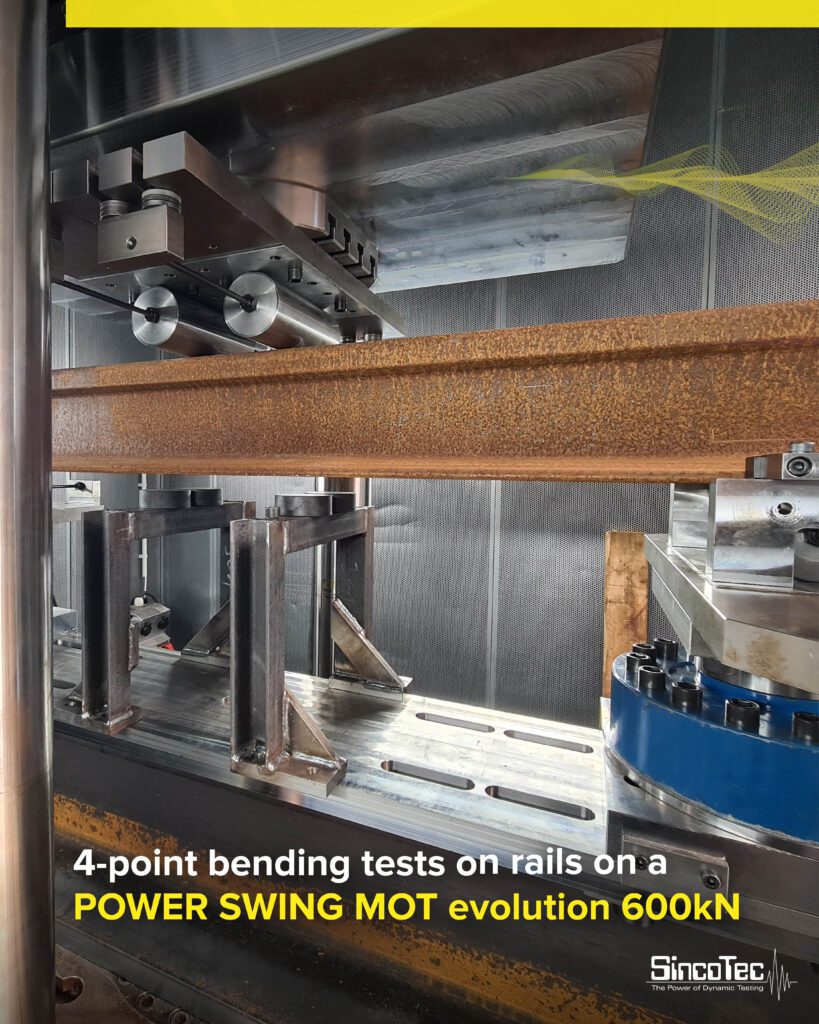

All tests were performed as vertical four-point bending fatigue tests using a clamping fixture specifically designed for this application, with adjustable support points and adjustable load introduction points.

The POWER SWING is based on the resonance principle, and compared with a conventional servo-hydraulic test rig, our setup is significantly more energy-efficient and faster.

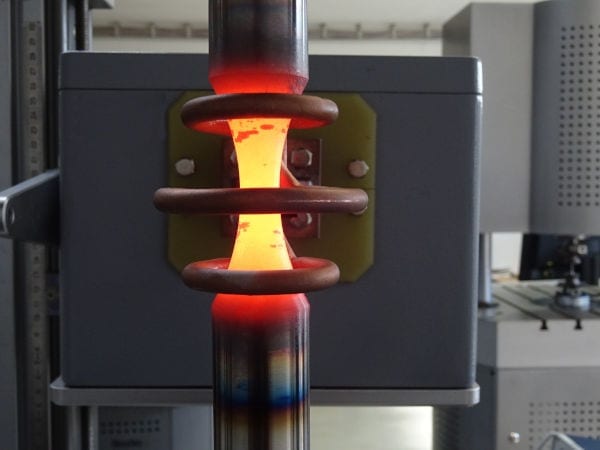

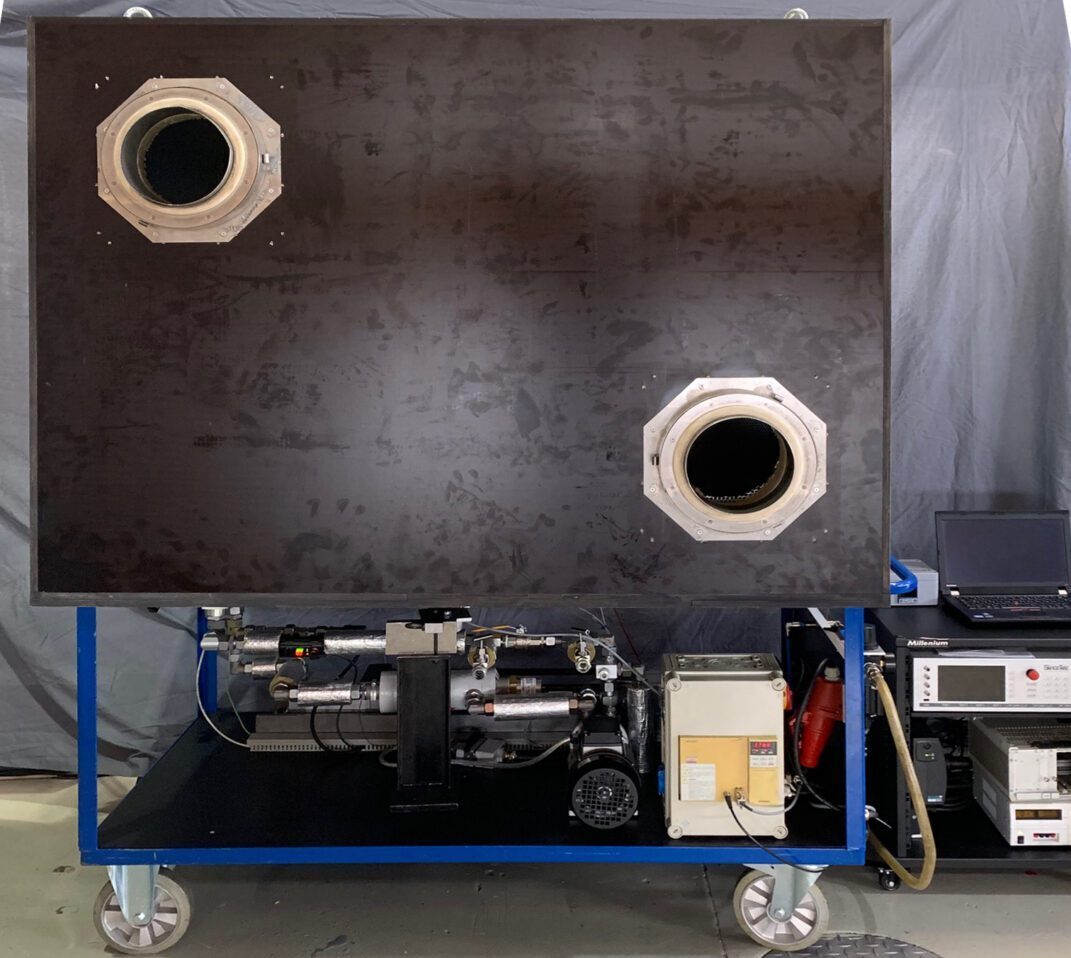

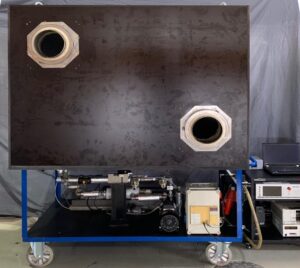

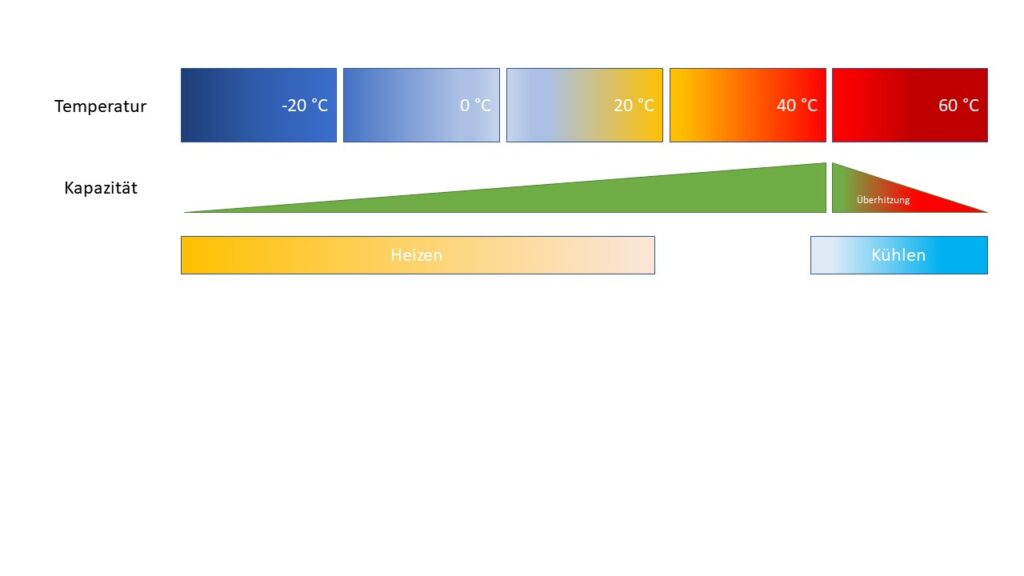

To also represent the effects of corrosion, selected specimens were pre-corroded in a test chamber and/or artificially aged prior to fatigue testing. For this purpose, we use our proven SALT LAKE conditioning unit, which provides a reproducible test solution for standard-oriented corrosion testing.

Would you like to learn more?

We have dedicated an article to this topic in our SincoTec news 12/2025: Safely to the destination – POWER SWING ahead: Railway rails on the test system! SincoTec defines new standards in rail testing

Do you have any questions or would you like to discuss the topic further?

Feel free to call us directly or send us an email.

We provide personalized, individual advice—from individual tests to system solutions. Our fatigue strength experts will support you with your testing tasks. Let’s work together to make the world a safer place!